Table of Contents

The Boundary Brief: Science, Economics, and Regulation

The planet’s limits are being pushed to the breaking point, with serious implications for business and society. This chapter explores the science, economics, and policies shaping the path to a nature-positive future.

Crossing the Threshold: Why Our Systems Are at Risk

The Planetary Boundary on Pollution and Novel Entities refers to the safe operating space for introducing substances—plastics, chemicals, heavy metals—that the Earth can absorb without disrupting ecosystems. According to leading research, we’ve already surpassed this limit: more than 350,000 synthetic chemicals are circulating globally, many of them untested for long-term impacts.

For businesses, this matters because polluted ecosystems reduce resource availability, increase health costs, and invite stricter regulation. At the same time, shifting toward circularity—keeping materials in use and eliminating waste—represents a path to resilience and competitive advantage.

In this series, we’ll explore how pollution, waste, and circularity intersect with business transformation. Today’s post sets the stage for understanding why this boundary is so central to a nature positive future.

Nature & Business: The Economic Imperative for Change

Science tells us that pollution destabilizes ecosystems—reducing biodiversity, poisoning soils and water, and amplifying climate change. But the economic signal is just as loud: the World Bank estimates trillions in annual losses tied to pollution-related health impacts.

Industries are exposed in multiple ways:

- Dependencies: Companies depend on clean water, fertile soils, and healthy workers.

- Risks: Pollution creates liabilities, brand risks, and volatile input costs.

- Opportunities: Circular economy models—reuse, repair, recycling—unlock efficiency and innovation.

This isn’t an abstract risk. It’s a tangible force reshaping market dynamics. Understanding pollution as both a science and economics issue is the first step toward transformative strategies.

Patagonia is one of the most famous outdoor brands in the world and is also renowned for leading the pack when it comes to experimenting a different way of conceiving and running a business. It’s mission statement is bold and unusual: “We’re in business to save our home planet.”

In this episode of our podcast, #Reebot Business, we talked to Ryan Gellert, Patagonia’s former General Manager of the EMEA (Europe, Middle-East, Africa) region and current CEO about the big challenges of our time and the role that a business can and should play in addressing these.

Regulations on the Rise: The Evolving Policy Landscape

Waste used to be thought of as “the end of the line”—something to manage once products had been consumed. Today, waste is understood as a resource problem, a climate challenge, and a business risk. Governments are tightening the rules, investors are watching, and consumers are demanding better. The policy landscape on waste and pollution is shifting fast—and companies that keep pace can turn compliance into competitive advantage.

At the international level:

-

Basel Convention

Originally aimed at curbing toxic waste dumping, it now also regulates certain plastic waste streams.

-

UN Global Plastics Treaty (in progress)

Could become the “Paris Agreement for plastics,” focusing on reducing plastic at the source rather than only managing it at the end of life.

Europe has made waste and pollution policy central to its economic strategy. Think beyond recycling bins: the EU is pushing for systemic change—products designed to last longer, easier to repair, and simpler to recycle.

Single-use plastics are being phased out, Extended Producer Responsibility schemes are spreading, and ambitious targets are holding companies accountable for material recovery. For businesses, this isn’t just regulation—it’s a signal that the European market is evolving toward circularity. Those who adapt quickly will thrive; those who don’t risk being left behind in a market where “linear” models (take–make–waste) are increasingly obsolete.

-

European Green Deal

Anchors sustainability as a growth strategy.

-

Circular Economy Action Plan

Requires products to be more durable, repairable, and recyclable.

-

Single-use plastic bans

Rolling out across the EU to cut pollution at source.

-

Extended Producer Responsibility (EPR)

Companies are increasingly accountable for the lifecycle of their products.

Across the Atlantic, the U.S. picture looks more fragmented. Federal regulation on waste has lagged, leaving states to lead the way.

For companies, this patchwork approach can be challenging: one state may require packaging redesign, while another sets higher recycling targets. Yet it also shows that momentum is shifting. Businesses that treat U.S. regulations as “piecemeal” may be caught off guard when federal action eventually catches up—because public pressure and climate imperatives are pushing Washington in that direction.

-

State-level leadership

California, Oregon, and Maine are implementing EPR laws for packaging.

-

Plastic bans

Spreading across multiple states and municipalities.

-

Federal action emerging

While slower, growing public and political pressure is pushing Washington toward stronger national waste and pollution policies.

Why Businesses Need to Act Now

What’s emerging is clear: the policy tide is turning, fast. Waste and pollution are no longer the hidden costs of doing business—they’re front and center in how economies are being reshaped. Forward-looking companies aren’t waiting to be forced into compliance. They are anticipating regulation, redesigning their value chains, and investing in circular solutions that reduce both risk and cost.

Future-proofing in this context isn’t just about surviving the wave of regulation. It’s about positioning as a leader in a new, nature-positive economy—where waste becomes opportunity, and pollution prevention is not just a policy mandate but a competitive edge.

Nature Strategy in Action

Measuring impact is where strategy meets action, turning data into insights that drive change. In this chapter, we explore the KPIs behind pollution, waste, and circularity, and a real-world use case from the fashion industry.

The textile and clothing sector is a $2.4 trillion industry that employs 300 million people worldwide. Without change, the fashion industry will account for 26% of the world’s carbon emissions by 2050 (Ellen McArthur Foundation).

In 2020, textile was among the top sectors with environmental and climate change impacts on a Life Cycle Assessment basis.

- Generates GHG emissions of 121 MTCO2eq annually, around 270 kg CO2eq per person

- Responsible for 2-8% of the world’s GHG emissions

- Responsible for 20% of the world’s wastewater

- $100 billion lost due to under-utilization and lack of recycling

- 85% of all textiles are dumped each year, the equivalent of one garbage truck per second

- Responsible for 9% of annual microplastic losses to the ocean

- About 80% of textiles’ total climate change impact occurs in the production phase

Closing the loop: innovating for circularity in fashion

Fast fashion has captured the attention of consumers globally, a business model characterized by quickly produced, affordable, and on-trend clothing. It offers consumers the ability to keep up with rapidly changing styles at relatively low prices. The rise of disposable fashion has contributed to a culture of overconsumption, where clothing items are treated as short-term, disposable commodities rather than long-lasting investments. Boosted by innovations in supply chain management and the widespread influence of social media, the fast fashion market is projected to reach $197.05 billion by 2028 at a compounded annual growth rate of 8.5% (Fast Fashion Global Market Report 2024). It is important to note that the leading cause of growth in the fast fashion industry is the expansion of the youth population. Data from United Nations projects the global youth population to grow by 7.9%, to 1.3 million by 2030.

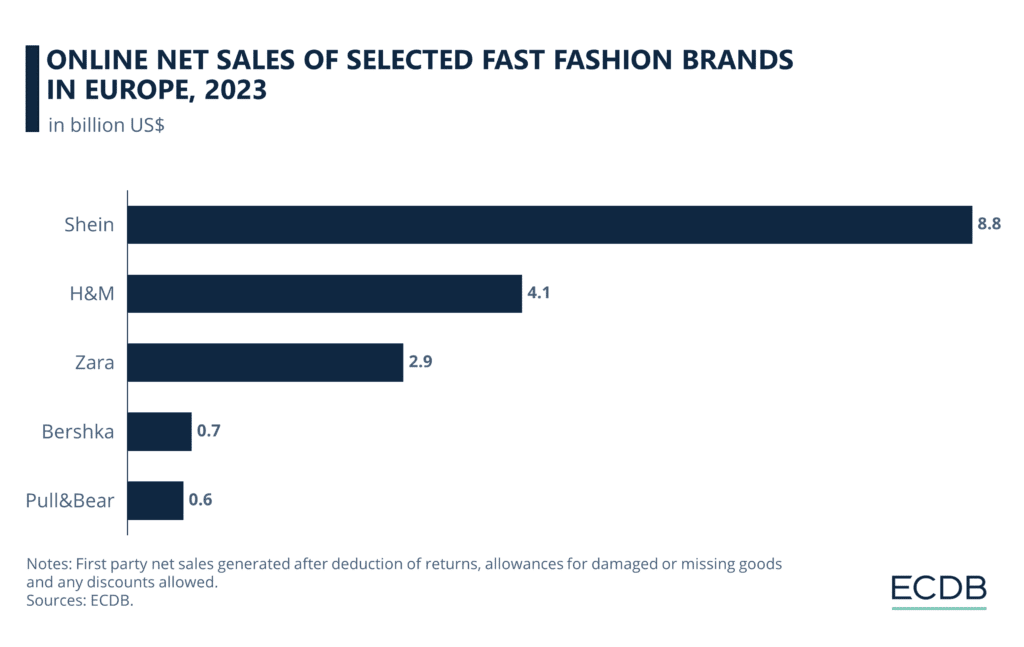

It is also impossible to neglect the recent emergence of what Harvard Business Review calls Instant Fashion. The most well known brand representing this newly developed business model is SHEIN. By incorporating the combination of mobile commerce, artificial intelligence, live shopping, and real-time, real-cheap product creation, the company was able to reach $1.5 billion in sales six years ago, and has since multiplied by more than 20 times, with its revenue target for 2025 exceeding $50 billion. With SHEIN’s unsustainable business model, the manufacturers churn out the same amount of CO2 as approximately 180 coal-fired power plants, emitting about 6.3 million tons of CO2 a year (Synthetics Anonymous 2.0).

Lu, the University of Delaware professor, found that in a recent 12-month period, the Gap listed roughly 12,000 different items on its website, H&M had about 25,000, and Zara had some 35,000. SHEIN, in that period, had 1.3 million.

Vauhini Vara in "Fast, Cheap, and Out of Control: Inside Shein’s Sudden Rise"

With the growing awareness of the negative impact the fast and instant fashion industry imposes, the EU has initiated to standardize Supply Chain Law which aims to reduce human rights violations and environmental malpractices in manufacturing locations. Marked by a strong and growing awareness among consumers regarding the environmental and ethical implications of their fashion choices, Europe seems to be swearing off fast fashion. According to Morgan Stanley research, the apparel industry is facing a structural decline as consumers cut back on the quantity purchased even with the drop in prices. More specifically, although the total market is increasing in value, the per capita consumption is plateauing. In fact, the world’s leading listed apparel retailers are experiencing earnings downgrade of, on average, 40% since the beginning of 2016.

On March 14th 2024, the French National Assembly adopted a legislation proposal aimed at reducing the negative impact of the fast fashion industry. The legislation aims to fight against fast fashion through multiple ways:

- establishing a criteria to qualify fast fashion brands malus points that will augment the products price up to 50%,

- a ban on advertisement for fast fashion

- the obligation to mention the negative impacts on e-commerce websites

France is the first country to legally look into limiting the impact of fast fashion, leading the way to other countries to aim for more sustainable fashion.

This legislation was pushed by the past decade of changes across the fashion industry. Brands are increasingly rejecting fast fashion principles that emerged thirty years ago and prone cheap clothing with many collections. The concept of slow fashion was introduced by Kate Flecther and the center of Sustainable Fashion, calling for efforts to close the loop in fashion and promote sustainable models.

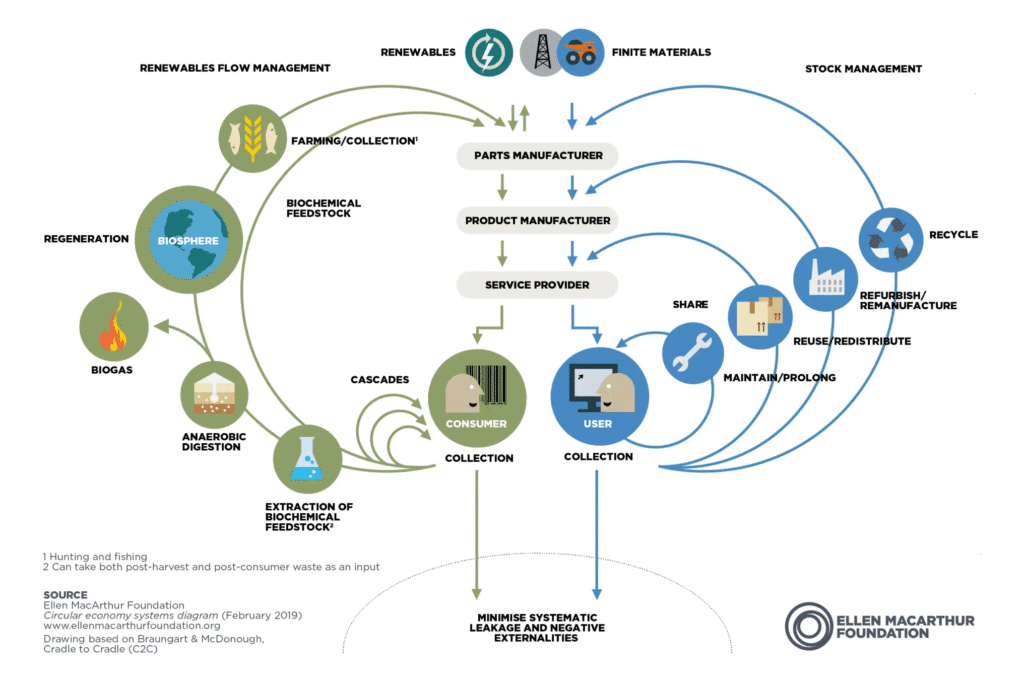

The Ellen MacArthur foundation established a vision for the fashion industry to introduce the circular economy concept in the way clothes are made and used. Fashion circularity means products to be used more, made to be made again, and made from safe and recycled or renewable inputs. The aim is to design items to prevent waste through designing them to be reusable, repairable, biodegradable and recyclable. It envisions the fashion industry as a closed loop in which materials are kept in use as long as possible.

At Impact Labs, we believe circularity should be the objective of fashion brands, and can be reached through putting in place a variety of models.

Client Spotlight: Prose – Redesigning the Delivery Box for a Circular Future

For Prose, a direct-to-consumer beauty brand specializing in personalized hair and skin care products, packaging isn’t just a box—it’s one of the largest contributors to their environmental footprint. While their on-demand production model already avoids waste from overproduction, Prose wanted to go further and confront the challenge of delivery packaging directly.

Rather than settle for incremental tweaks, Prose partnered with us to pilot a bold alternative: reusable delivery boxes. The aim was to test how circular packaging could reduce waste, lower emissions, and set a new standard for sustainable e-commerce.

The results speak for themselves:

-

Carbon break-even after just two uses...

proving reusables outperform single-use packaging quickly.

-

A scalable model...

that demonstrates how circular solutions can deliver real impact for both planet and business.

This case illustrates a powerful lesson: even small-seeming interventions—like rethinking the humble shipping box—can unleash massive positive change. Prose’s pilot proves that sustainability doesn’t have to come at the cost of customer experience; in fact, it can redefine what responsible, modern beauty looks like.

Sustainable Fashion Models: Circularity in Action

The fashion industry is a major environmental and social force, but innovative business models are helping brands reduce their footprint and embrace circularity. Key strategies include:

-

Ethics & Transparency: Brands like Kotn showcase their supply chains and ensure fair labor practices.

-

Longevity & Repair: Patagonia and platforms like Prolong extend garment life through durable design and repair services.

-

Zero Waste & Upcycling: Designers like Katla use efficient patterning, while Elvis & Kresse transform waste materials into luxury goods.

-

Rental, Subscription & Pre-Order Models: MUD Jeans and Rent the Runway reduce overproduction by enabling product sharing and leasing.

-

Second-Hand Marketplaces: Platforms like Reflaunt facilitate resale, extending product life and promoting circular consumption.

-

Regenerative Practices: Patagonia’s Regenerative Organic Certified® (ROC) label integrates soil health, biodiversity, animal welfare, and social fairness, demonstrating how brands can drive systemic impact.

An example of excellence

Regenerative Organic Certification

Despite being a significant global economic force, the fashion industry engenders considerable social and environmental challenges. There is an urgent need to change current trends that lead to big carbon footprints and substantial waste around the world. This urgency is highlighted by past disasters like the 2013 Rana Plaza collapse which exemplifies the terrible working conditions behind fast fashion. At Impact Labs, we believe innovations in sustainable business models and technology solutions that promote circularity point towards a new horizon for the fashion industry, fostering more responsible consumption and production patterns. These shifts are crucial around the world, as increasing efforts are made to align with sustainability targets and ethical standards.

The Future of Circularity: Innovative Tools and Tech Solutions

Explore how digital innovation is transforming the way businesses measure resource efficiency, track circular performance beyond carbon, and leverage data to drive a nature-positive transition.

Tracking What Matters: Metrics for Resource Efficiency

Metrics are the bridge between ambition and action. Businesses can’t reduce pollution or improve circularity without knowing where they stand. Some widely used indicators include:

- Waste generation per unit of revenue or product

- Recycling and recovery rates

- Hazardous waste intensity

- Material Circularity Indicator (MCI)

- Waste-related scope 3 emissions

These metrics reveal hidden inefficiencies and create accountability. While not yet standardized across industries, they offer a way forward for companies to make pollution visible, track progress, and align with planetary boundaries.

Beyond Carbon: The Tech Revolutionising How We Measure Circular Impact

For decades, environmental performance has been reduced to a single headline number: the carbon footprint, measured in tonnes of CO₂ equivalent. Essential, yes—but dangerously incomplete. Carbon alone doesn’t capture the full story of resource use, circularity, and regeneration.

As businesses shift towards a circular economy, they need a richer lens—one that measures not only what is being avoided, but what new value is being created.

From End-of-Pipe to Systemic Impact

Most companies begin their circular journey with simple metrics: waste volumes, recycling rates, landfill diversion. These are useful starting points, but they are narrow and reactive. They describe the end of the pipe, not the system that produced the waste in the first place.

The real transformation happens when businesses start measuring across the whole lifecycle: optimising resources, extending product value, and even generating positive resource flows.

New Metrics for a New Economy

As companies mature, their metrics evolve from compliance checkboxes to strategic value creators. Three examples show what this shift looks like:

-

A Three-Fold Impact (Reflaunt, Fashion):

Reflaunt’s resale platform tracks avoided impacts across CO₂, water, and energy. By extending the life of clothing, they’ve already saved 156 tonnes of CO₂, 13.7 million litres of water, and 673,000 kWh of electricity—proof that circular business models can deliver tangible resource savings.

-

Measuring Enablement (Circuly, PaaS):

Circuly doesn’t just track direct resource use—it measures how many companies it has enabled to transition to subscription and rental models. The metric captures systemic influence, reflecting the ripple effect of enabling other businesses to go circular.

-

The Value of Time (Circonomit, Data Intelligence):

Circonomit treats time itself as an impact measure. By automating data collection and linking sustainability metrics with financial decision-making, they free up client teams to act on insights rather than wrangle spreadsheets—time that directly translates into accelerated progress.

Together, these examples illustrate a crucial mindset shift: impact is no longer only about what we reduce, but about what regenerative value we create.

The Tech Making It Possible

This evolution in impact measurement is powered by a suite of digital technologies. They transform sustainability from a backwards-looking reporting task into a forward-looking strategic tool:

-

AI & Advanced Analytics

Identify resource inefficiencies and optimise processes across entire value chains. Diversys uses AI to automate waste-tracking data, providing real-time reporting against chosen sustainability metrics.

-

IoT & Digital Twins

Sensors track product lifecycles and material degradation, while digital twins model circular systems to simulate “what if” scenarios before they go live.

-

Blockchain & Digital Passports

Immutable records guarantee transparency. Reath uses these tools to power in-store refill systems, scaling circular solutions safely across retail networks.

-

Integrated Platforms

Tools like Circonomit connect sustainability KPIs with financial performance, while Optoro uses proprietary algorithms to manage product returns with precision, cutting both costs and waste.

The future of impact measurement isn’t about producing glossy reports—it’s about generating real-time intelligence that drives decisions, unlocks efficiency, and builds resilient, regenerative systems.

Carbon footprints will always matter. But in the age of the circular economy, they are only one piece of the puzzle. The leaders of tomorrow will be those who measure the full picture—and use technology to turn data into transformation.

Our Circularity Tech Radar categorizes digital tools across six areas—supply chain transparency, resale platforms, reverse logistics, waste prevention, product-as-a-service models, and smart packaging—and details how technologies like AI, IoT, and blockchain facilitate the shift to a Circular Economy. It provides examples of companies, such as Reflaunt, Optoro, and Circuly, that offer innovative digital solutions to quantify impact and advance circularity, underscoring the importance of holistic impact measurement beyond traditional metrics.

Go Circular or Go Home: The Digital Road to a Nature-Positive Business

Our planet is sending a loud warning. The linear “take–make–waste” economy has reached its limits. In just five years (2018–2023), humanity consumed 28% of all the materials used since 1900. That surge has pushed six of nine Planetary Boundaries beyond their safe operating space. And while the pressure on nature grows, global circularity has actually fallen by 21%.

The conclusion is unavoidable: the linear model is broken.

The solution is a fundamental redesign of how we use resources—through the circular economy, a regenerative system where materials are reused, refurbished, and safely returned to nature. This is not simply an environmental aspiration. It’s a business imperative. And at the heart of this transformation sits an unexpected driver: digital technology.

Technology is resource-intensive—hardware, rare minerals, and energy-hungry data centers all leave a heavy footprint. Yet it is also the most powerful lever we have for change. The same digital tools that drive today’s consumption patterns are also enabling tomorrow’s regenerative systems.

By embedding transparency, traceability, and efficiency into every stage of a product’s life, digital innovation is making circularity not only possible, but profitable.

The Digital Innovations Powering Circularity

The transition to a circular economy is being accelerated by a new digital toolkit. Together, these innovations are weaving a web of solutions that can transform value chains into regenerative ecosystems:

-

Radical Supply Chain Transparency

What you can’t see, you can’t manage. Blockchain and Digital Product Passports create permanent records of origin, composition, and lifecycle, giving companies and consumers full visibility. Platforms like **Reath** already use machine-readable codes (QR, RFID) to track reusable packaging and keep materials in circulation.

-

Second Life Marketplaces

Extending product lifecycles is central to circularity. AI-powered resale platforms such as Reflaunt integrate directly with luxury brands, enabling them to participate in the second-hand market while empowering customers to resell, donate, or recycle with ease.

-

Smarter Reverse Logistics

Returns, repairs, and refurbishments are no longer logistical headaches. Data-driven platforms like Optoro optimise routes and decisions for returned goods, determining the most valuable and sustainable outcome for each product.

-

Designing Waste Out

Prevention beats cure. With AI, IoT sensors, and predictive analytics, companies can monitor resource use in real-time and redesign processes to eliminate waste before it exists. Diversys, for example, automates waste tracking and reporting to reveal the hidden value in recyclables.

-

From Ownership to Access

The Product-as-a-Service (PaaS) model flips the script. Instead of selling units, companies offer services—encouraging longevity, reuse, and efficiency. Circuly’s subscription platform helps businesses rent products rather than sell them outright, reducing the demand for new production (and its embedded emissions).

-

Intelligent Products & Packaging

With smart packaging powered by IoT and digital passports, products can “tell their story”—where they came from, how they’re made, and how to recycle or return them. This transparency empowers customers to make choices that close the loop.

These innovations are not standalone solutions. Their real power emerges when connected—forming a digital backbone for a circular economy. In this model, materials are no longer “used up” but continually reimagined. Products become value streams. Waste becomes data.

For business, the choice is stark: adapt and thrive in a circular, nature-positive economy—or remain locked in a linear system that is already breaking down.

The road ahead is clear: go circular, or be left behind.